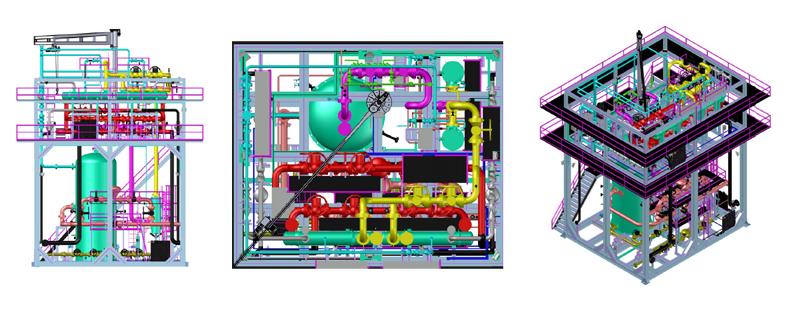

Natural Gas Filtration, Regulating & Metering System

THAKETA – MAX POWER

Process Condition

-

Pr I/L; 400 Psig,

Pr O/L; 150 Psig - Design Pressure: 600 Psig

- Flow: 40MMSCFD

- Temp: 60 – 120 deg F

Filtration 40MMSCFD

- 2 x 100% capacity

Pr Regulating; 20 / 40MMSCFD

- 2 x 50% capacity

- 1 x 100% capacity

- 4”, 300 # Reg – 4nos

- 4”, 300 # CV – 1no

Safety Device; 40 / 4MMSCFD

- 4”, 300 # SSV – 2nos

- 6”, 300 # SSV – 1no

- 1.5” x 2” ” CRV – 2nos

- 4” x 4” PSV – 1no

Metering; 40MMSCFD

- 2 x 100% capacity

- 10”, 300 # Senior Orifice Meter

Gas Train for Gas Engine

MANDALAY POWER STATION

Process Condition

-

Pr I/L; 400 Psig,

Pr O/L; 70 Psig - Design Pressure: 650 Psig

- Flow: 40MMSCFD

- Temp: 70 – 100 deg F

Filtration 40MMSCFD

- 1 x 100% capacity

Pr Regulating; 5MMSCFD

- 8 x 10% capacity

- 2”, 300# Reg – 16nos

Safety Device; 40 / 4MMSCFD

- 2” x 3” CRV – 8nos

Metering; 40MMSCFD

- 1 x 100% capacity

- 10”, 300 # Senior Orifice Meter

Natural Gas Filtration, Regulating & Metering Skid

MANDALAY GAS-FIRED CCPP

Process Condition

-

Pr I/L; 600 Psig,

Pr O/L; 300-400 Psig - Design Pressure: 650 Psig

- Flow: 40MMSCFD

- Temp: 70 – 100 deg F

Filtration 40MMSCFD

- 2 x 100% capacity

Pr Regulating; 20 / 40MMSCFD

- 2 x 50% capacity

- 1 x 100% capacity

- 4”, 600 # Reg – 4nos

- 6”, 600# CV – 1no

Safety Device; 40 / 4MMSCFD

- 4”, 600 # SSV – 2nos

- 1.5” x 2” CRV – 2nos

- 1.5” x 3” CRV – 1no

Metering; 40MMSCFD

- 2 x 100% capacity

- 10”, 600 # Senior Orifice Meter

Fuel Gas Treatment Package

FPSO, MERO 3, BRAZIL

Water Treatment Package

Dosing System

- Capacity: 1000 Litres

- Design Code: ASME Sec VIII Div 1

- Design Pr: 3.5 barg

- Design Temp: 60 deg C

- Process Medium: Ethyl Mercapton

- Hydro Test Pr: 5.5 barg

- Size: 900mm (ID) X 1800mm (H) X 5mm (T)

- Matl: SS316

Water Treatment Package

Dosing System

Process Condition

- Design Pr: 4 barg

- Design Temp: 60 deg C

- Hydro Test Pr: 4 barg

- Matl: CPVC

ASME U-Stamp SS304 Vessel – Odorization System

TITAS GAS TDCL, BANGLADESH

- End User : TITAS Gas Transmission & Distribution Company Ltd., Bangladesh.

- Project : Natural Gas Odorization System.

ASME U-Stamp, SS304 Vessels :

- Design Standard : ASME Sec VIII Div 1.

Process Condition:

- Medium : Natural Gas

- Pressure : 300 PSIG

- Temperature : 65 degC

- Flow : 12 MMSCFD

- Odorant : THT / Mercaptan

Heading & Unheading System

BINA REFINERY – COKE CHAMBER PROJECT

Process Condition

- Medium : MP Steam

TUD Steam Purge System

- Flow : 120 kg/h

- Pressure : 18 / 22 barg

- Temp : 260 / 350 degC

BUD Steam Purge System

- Flow : 800 kg/h

- Pressure : 18 / 22 barg

- Temp : 260 / 350 degC

- Total Systems (Qty) : 04sets

- Design Code : ASME B31.3 + IBR

Hazardous Area:

- Zone2, Gas Group IIA/IIB, T3 Certification

- According to ATEX, IBR CCOE

- Ignition Protection Type : Exia

PURGING & CONDENSATE SYSTEM

Dosbocas Refinery, Mexico

Process Condition

- Medium : MP Steam

TUD Steam Purge System

- Flow : 250 Kg/hr

- Pressure : 18 / 20 kg/cm2

- Temp : 260 / 300 degC

BUD Steam Purge System

- Flow : 1000 Kg/hr

- Pressure : 18 / 20 kg/cm2

- Temp : 260 / 300 degC

ASME U-Stamp SS316L Condensate Vessel (140L)

- Flow : 1000 Kg/hr

- Pressure : 18 / 20 kg/cm2

- Temp : 260 / 300 degC

Total Systems (Qty) : 12 sets

PURGING & CONDENSATE SYSTEM

IOCL BONGAIGAON REFINERY

Process Condition

- Medium : MP Steam

TUD Steam Purge System

- Flow : 70 / 230 Kg/hr

- Pressure : 17 / 18 kg/cm2

- Temp : 205 / 300 degC

BUD Steam Purge System

- Flow : 250 / 1000 Kg/hr

- Pressure : 17 / 18 kg/cm2

- Temp : 205 / 300 degC

ASME U-Stamp SS316L Condensate Vessel (140L)

- Flow : 1000 Kg/hr

- Pressure : 17 / 18 kg/cm2

- Temp : 205 / 300 degC

Total Systems (Qty) : 6 sets

PURGING SYSTEM

Salina Cruz Refinery, Mexico

Process Condition

- Medium : MP Steam

TUD Steam Purge System

- Flow : 50 / 250 Kg/hr

- Pressure : 10 / 13.5 kg/cm2

- Temp : 210 / 230 degC

BUD Steam Purge System

- Flow : 250 / 1000 Kg/hr

- Pressure : 10 / 13.5 kg/cm2

- Temp : 210 / 230 degC

Total Systems (Qty) : 8 sets

CONDENSATE SYSTEM

Salina Cruz Refinery, Mexico

Process Condition

- Medium : MP Steam

TUD / BUD Condensate System :

ASME U-Stamp SS316L Condensate Vessel (140L)

- Flow : 1000 Kg/hr

- Pressure : 10 / 13.5 kg/cm2

- Temp : 210 / 230 degC

Total Systems (Qty) : 8 sets

PURGING & CONDENSATE SYSTEM

CEPSA REFINERY, SPAIN

Process Condition

- Medium : MP Steam

Steam Purge System

- Flow : 80 / 105 Kg/hr

- Pressure : 6 / 6.8 kg/cm2

- Temp : 170 / 250 degC

Condensate System :

- Flow : 115 Kg/hr

- Pressure : 3.11 / 4.6 kg/cm2

- Temp : 250 / 300 degC

Total Systems (Qty) : 1 set

PURGING & CONDENSATE SYSTEM

REPSOL REFINERY, SPAIN

Process Condition

- Medium : MP Steam

Steam Purge System

- Flow : 100 / 165 Kg/hr

- Pressure : 20.6 / 25.9 kg/cm2

- Temp : 310 degC

Condensate System :

- Flow : 165 Kg/hr

- Pressure : 2.2 / 3.5 kg/cm2

- Temp : 310 / 343 degC

Total Systems (Qty) : 1 set

AIR VOLUME TANKS

IOCL, INDIA

Process Condition

- Medium : Air

- Capacity : 1000 Gallon

- Operating Pr : 3.5 kg/cm2

- Design Pr: 11.62 kg/cm2

- Design Temp: 150 deg C

- Design Code: ASME Sec VIII Div 1

- Hydro Test Pr: 17.43 kg/cm2g

- Size (mm): 1219 (OD) X 4900 (H)

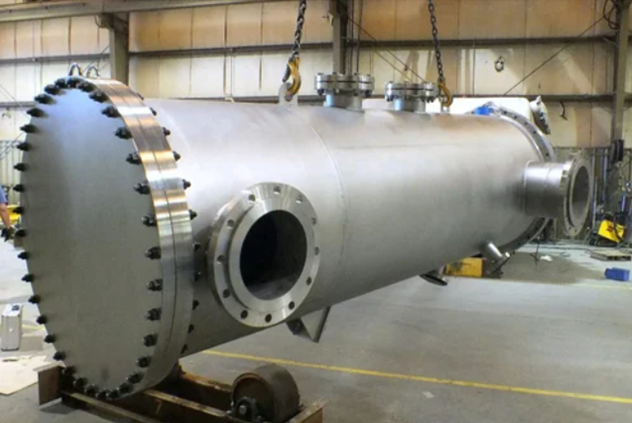

HEAT EXCHANGER (Shell & Tube)

GAIL USAR, INDIA

Heat Exchanger (ASME U-STAMP)

Shell Side:

- Medium: Water

- Pressure: 0.45 Mpa(g)

- Temperature: 33 deg C

- Material : Carbon Steel

Tube Side:

- Medium: QUINTOLUBRIC® 888-46 (FIRE-RESISTANT HFD-U HYDRAULIC FLUID)

- Pressure: 0.5 – 0.6 Mpa (g)

- Temperature: 45 - 50 deg C

- Material : SS316

HEAT EXCHANGER (Shell & Tube)

Heat Exchanger

Shell Side:

- Medium: Water

- Pressure: 3.3 kg/cm2g

- Temperature: 30 deg C

- Material : Carbon Steel

Tube Side:

- Medium: OIL

- Pressure: 4.2 kg/cm2g

- Temperature: 44 deg C

- Material : Stainless Steel

HEAT EXCHANGER (Shell & Tube)

Heat Exchanger (Fuel Gas)

Shell Side:

- Medium: Water

- Pressure: 10 Barg

- Temperature: 120 deg C

- Material : Stainless Steel

Tube Side:

- Medium: Fuel Gas (CO2 Gas)

- Flow Rate : 15 MMSCFD

- Pressure: 25 Barg

- Temperature: 12 – 45 degC

- Material : Stainless Steel

HEAT EXCHANGER (Shell & Tube)

Kothari PetroChemicals Ltd

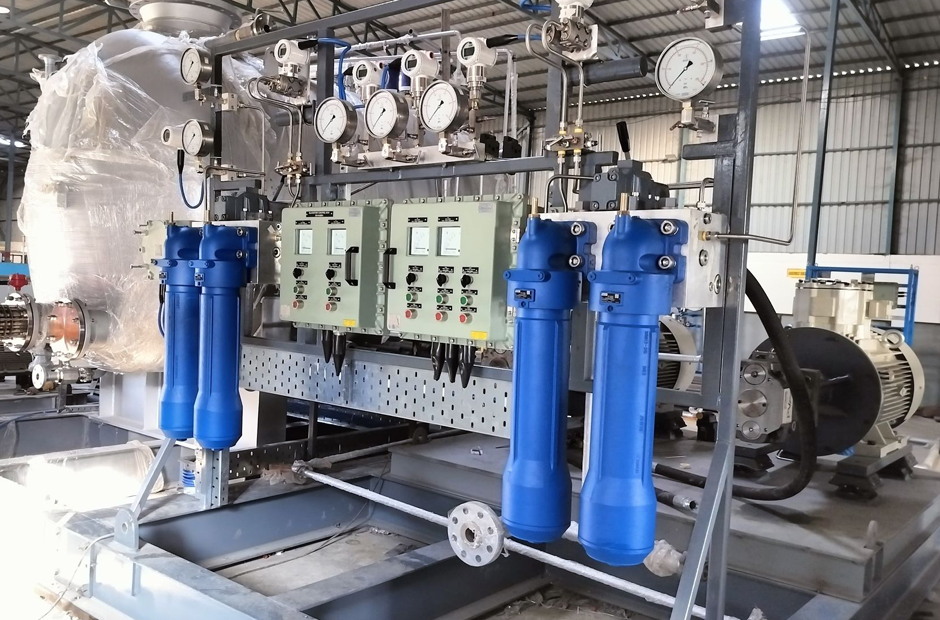

HYDRAULIC CONTROL UNIT

GAIL USAR, INDIA

Process Condition

- Medium : Oil

- Flow : 250 Litre/Min

- Pressure : 16 Mpa(g)

- Temp : 0-45 degC

Total Systems (Qty) : 35 sets

HYDRAULIC POWER UNIT

GAIL USAR, INDIA

Process Condition

- Flow: 250 Litre/Min

- Pressure: 160 bar

- Temperature: 45 deg C

- Tank: Capacity 10,000 Litres

Pump & Motor Station 1

- Pump: Capacity: 250 Litre/Min

- Pump Discharge Pr: 16 Mpa (g)

- Motor: 110kW, 415V, 3PH, 50Hz, 1450 rpm

Pump & Motor Station 2

- Pump: Capacity: 200 Litre/Min

- Pump Discharge Pr: 0.8 Mpa (g)

- Motor: 7.5kW, 415V, 3PH, 50Hz, 1450 rpm